Exterior Use

Western juniper has a very high natural resistance to decay. In fact, in an Oregon State University study that has been ongoing since 1928, western juniper fence posts were reported to last 30+ years, longer than any other untreated western species (Morrell, 1999). Another study has shown that western juniper heartwood shows excellent resistance to termite and fungal attack, even in tropical climates (Morrell, 2010). This natural resistance to decay, and its long history of use for fence posts has led many to experiment with western juniper for other outdoor uses such as patio furniture, fences, siding and decking. If used and maintained properly, juniper can last for many years outdoors.

Some of the items that should be considered when using juniper wood outdoors are: tendency to warp when long lengths are used, size and quantity of knots, nail withdrawal strength, mix of heartwood and sapwood for each board, and low stiffness strength. None of these items indicates that juniper cannot or should not be used for exterior applications. The main idea is simply to take these items and others you are aware of into account when considering an exterior end use for juniper.

Short stems and a high degree of taper make it difficult to obtain long, wide boards from most juniper logs. Long boards sawn from juniper tend to warp and twist, making them difficult to use. The factors causing the warp may be juvenile wood, the effects of growth stresses, and cross-grain. The grain distortion caused by large knots may also lead to somewhat unpredictable warp and reduction in strength for certain applications.

Nail withdrawal strength is actually a plus for juniper if applied properly. Tests have shown that juniper holds a nail very well and does not tend to split if nailed near end grain. This can help to alleviate some of the nail popping and warp that can happen on a deck surface. Remember, however that in order to realize this benefit, the deck board must be nailed to a piece of juniper. In other words, if juniper is used for deck surface material, and pressure treated Douglas-fir is used for joists, then the improved nail withdrawal strength is not obtained.

It is quite rare to see a juniper board of any significant size that is pure heartwood or pure sapwood. As with all naturally decay resistant woods, it is only the heartwood that provides the decay resistance. The sapwood of an untreated juniper board exposed to the elements is no more decay resistant than non- durable woods such as white fir, ponderosa or lodgepole pine. People have commented that the sapwood of juniper fence posts has rotted away after just a few years, leaving a core of decay resistant heartwood. Does this mean that juniper can't be used outdoors? Certainly not. Juniper lumber should hold up quite well if treated and frequently maintained with a water repellent preservative or finished with a stain or paint of some kind.

The effect of low strength in bending stiffness is not likely to be a problem unless juniper is used in long spans without adequate support. Juniper is only about 70% as stiff as ponderosa pine, and only about 85% as stiff as incense-cedar. In other words, juniper bends relatively easily under a load. This property may be important for applications such as decking, benches, chairs, or picnic tables. For decking surface material, juniper may need to be supported more often than traditional species. The standard is to have joists 24 inches on center for nominal 2 inch deck material and 16 inches on center for 5/4 deck material. Nominal 2-inch juniper decking may require the 16 inches on center spacing in order not to feel "spongy" when walked on. For a long bench seat, extra bracing may be required to prevent deflection.

When using juniper for outdoor applications, remember that any wood used outdoors is subject to severe moisture and temperature changes, attack by decay organisms, degradation due to UV light from the sun, and surface abrasion. For all these reasons, it is important to maintain the wood over time.

One of the harshest situations wood faces is contact with soil. Soil contact helps to raise the moisture content of wood and provides an easy avenue for insects and decay fungi to move into the wood and destroy it. Fence post durability studies conducted at Oregon State University's Department of Forest Products have shown that western juniper fence posts can last 30 years or more, longer than any other western wood species. As mentioned before, however, the sapwood is not decay resistant.

Western juniper sapwood in contact with soil may be preserved with store bought, brush-on preservatives. According to Dr. Jeff Morrell, wood preservation expert at Oregon State University, the "over-the- counter" preservatives best suited for wood in contact with soil contain copper naphthenate. Brands such as Behr Dock & Fence Post Preservative and Cuprinol contain 2% copper naphthenate, the concentration recognized by the American Wood Preservers' Association as being most effective for preventing decay. In 1996, these preservatives were sold at home centers in Klamath Falls, Oregon for about $15-$20 per gallon.

Juniper used outdoors that is not in contact with soil still faces a tough service life. Finishes are used to help slow the degrading action of moisture, UV light from the sun, and abrasion from foot traffic and windblown debris. There are many types of finishes available, but the majority fall into 2 broad categories: penetrating and film-forming.

Penetrating finishes such as water-repellents and semi-transparent stains are absorbed into the wood and provide short-term protection against decay. The duration of protection is increased for penetrating finishes that contain preservatives. Film-forming finishes such as paints are generally unsuitable for horizontal surfaces such as decks. The film created by film-forming finishes is broken at the gap between boards, allowing water to enter the wood through the board edges. As wood absorbs water it swells. Swelling can cause the film to split, opening gaps for water to enter the surface of the wood. As the moisture content of the wood is raised high enough (above roughly 19%), decay organisms are then able to begin destroying the wood. Film-forming finishes may also be scuffed off deck surfaces due to foot-traffic.

Questions often asked about finishing wood outdoors include:

Q. Which type of surface is recommended for best finish performance- rough or smooth?

A. Past studies have shown that finishes applied on rough surfaces performed better than those on smooth surfaces. The primary reason for this was probably the difference in spread rate. If you've ever tried to paint or stain a very rough surface (such as rough-sawn cedar fencing) you know it takes a great deal more time and finish to adequately cover rough surfaces compared to smooth ones. The higher amount of stain used on rough surfaces is the reason these surfaces performed better than smooth surfaces. The USDA's Forest Products Laboratory recently conducted a study on stain performance for rough versus smooth surfaces. This study showed that a sanded surface performed better than both a rough surface or a surface finished with a planer. The sanded surface also required less than half the amount of stain as did the rough surface.

Q. Do pigmented (colored) finishes perform better than clear?

A. While clear finishes allow the natural color of the wood to show and may protect against moisture and mildew, most do little to protect from UV degradation (though some clear finishes now have "UV protectors"). The sun's UV rays break down the wood, accelerating the weathering process and causing the wood to turn gray. Mildew is also a major reason for the gray-black coloration in wood used outdoors in wetter envrionments. The beautiful "marbled" coloration of juniper will weather to a dull gray in just 1 to 2 years of exposure. The pigment in colored finishes helps shield the wood from UV light and therefore may slow the weathering process. The pigment also protects the preservative in the finish and therefore increases the life of the preservative. Clear finishes may perform adequately if the manufacturer's recommended rates of re-application are followed. Re-application rates vary from several times per year to once every 2 years.

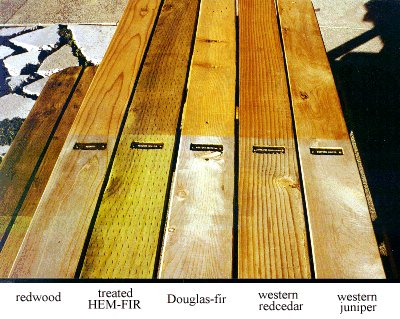

The picnic table in the photo above shows the effects of weathering on several wood species commonly used for exterior applications. Half the surface of the table (the upper half of the table in the photo) was finished with a penetrating finish- a water repellent preservative with UV protection and half was left unfinished. The sun's UV rays and moisture work together to "bleach" away wood's natural color. The photo was taken after just 2 months of exposure.

Western juniper in exterior use can withstand the elements and provide years of enjoyment provided it is used and maintained properly.

References:

Morrell, J.J., D.J. Miller, and P.F. Schneider. 1999. Service life of treated and untreated fence posts: 1996 post-farm report. Research contribution 26. Forest Research Laboratory publications, Oregon State University.

Morrell, J.J. 2010. Decay and termite resistance of western juniper sapwood and heartwood under tropical conditions: 32-month report.

State of Oregon Building Codes Division, 2010. Western Juniper Naturally Durable Wood

For more information:

USDA Forest Products Laboratory Publications, Painting & Finishing Factsheets

Acknowledgements: My thanks to Mark Knaebe at the USDA's Forest Products Laboratory in Madison, WI for reviewing and providing comments on the information in this article.

The information given here is supplied with the understanding that no discrimination is intended and no endorsement by the Cooperative Extension Service is implied. Trade names (brand names) of some commercial preservatives are given for informational purposes only.