Improvements in the Methods of Bending the Wood of Western Juniper

Improvements in the Methods of Bending the Wood of

Western Juniper (Juniperus occidentalis Hook.)

Report of 15 December, 1999

Edwin J. Burke

Missoula, Montana

eburke@forestry.umt.edu

Introduction

As previously reported, wood of western juniper, Juniperus occidentalis Hook., that had been water-saturated, and either heated or unheated, displayed great flexibility during vertical veneer slicing trials conducted in 1993 at Rogue Valley Sash and Door, Grants Pass, Oregon. According to the guillotine-slicer operator, it was the most "noodly" species he had ever seen (Swan, 1993). Burke later found that thin (0.100 inch to 0.250 inch) strips of clear, straight-grained material could be easily bent to shape using common tools and preparation equipment.

In the original trials, two methods of preparation were used: Resaturation in boiling water followed by steeping in live steam (soak/steam bending), and resaturation only (soak bending). Saturation was judged complete when air bubbles no longer escaped from the wood’s surface, and the strip sank to the bottom of the container. For water soak/steam bending, strips were first placed in boiling water for 3-5 minutes, then lifted from the water and allowed to steep in live steam generated at ambient pressure for another 2-3 minutes.

Thin strips (0.100 inch to 0.250 inch) were sawn from clear, straight-grained 4/4 lumber cut from trees harvested near Klamath Falls, Oregon. Two methods of preparation were used: Resaturation in boiling water followed by steeping in live steam (soak/steam bending), and resaturation only (soak bending). Saturation was judged complete when air bubbles no longer escaped from the wood’s surface, and the strip sank to the bottom of the container. For water soak/steam bending, strips were first placed in boiling water for 3-5 minutes, then lifted from the water and allowed to steep in live steam generated at ambient pressure for another 2-3 minutes. After preparation by both methods, sample pieces were bent into several shapes including helices, overhand knots, spirals, circles and several combinations of all these. Minimum radii of curvature were approximately 0.750 inch for 0.125 inch thick pieces.

This early study found that minimum attainable radius of curvature for western juniper bentwood products decreased with decreasing stock thickness, with 0.75 inch the minimum practical radius for 1 inch wide x 0.125 inch thick strips. Conclusions included not recommending use of bent western juniper wood in areas of high heat and humidity, as springback was noticeable.

After preparation by both methods, sample pieces were bent into several shapes including helices, overhand knots, spirals, circles and several combinations of all these. Minimum radii of curvature were approximately 0.750 inch for 0.125 inch thick pieces. Results of the demonstration showed that average springback (straightening) after cooling only was approximately 5 degrees/360 degrees of helix. When sample pieces were allowed to dry under restraint in the forms at room temperature, springback of the helices averaged approximately 3 degrees/360 degrees of helix. Rewetting of the bent helices in cold water for 10 minutes resulted in approximately 60 degrees/360 degrees of springback, while 3 minutes in boiling water resulted in nearly 120 degrees/360 degrees of springback. Other shapes were also subjected to springback tests and behaved in a similar fashion.

Methods and Materials of the Current Study

This study also used thin (0.125 inch) strips, 1 inch wide strips of clear, straight-grained western juniper bent into small-radius coils and knots. The method was altered, however, to bend the small radii coils in stages. The first stage consisted of preparing the strips by boiling in water and coiling them inside heated 3 inch diameter (inside) polyvinyl chloride (PVC, 1/4 inch thick wall, Drain, Waste and Vent) pipe. The spirals were allowed to air cool while inside the pipe section, then while still in place in the pipe sections, placed once more into the boiling water for 30 seconds to resoften the wood. The coils were then gradually removed removed by screwing out the strip and placing it into heated 2 inch inside-diameter PVC pipe. The new, tighter spiral was then allowed to cool in the pipe and then placed in an oven at 250 degrees F for approximately 45 minutes. The pipe/ wood coil assembly was then removed from the oven and allowed to cool for an additional 30 minutes prior to removal of the coil from the pipe. The coil was then replaced in the oven for another 45 minutes until dry.

Springback is small using this 2-step process for bending coils from thin strips of western juniper, averaging approximately 1/4 inch diameter increase when removed from the pipe after final drying. The permanent set taken on by the bent wood is partially recoverable by placing the coil into boiling water, but in normal use it can be repeatedly compressed and expanded without breakage loss of curvature. This two step method is more time consuming, but it produces a product of smaller radius than single-stage bending.

Implications for Industry

- Thin, bent-wood western juniper products produced by two-stage hot-water heating and bending in a form can be formed into tighter-radius products than single stage hot-water or steam bending.

- Following the second stage of heating and forming, oven drying while held fixed in the form will produce at least 50% smaller radius bends than can single stage bending.

- Use of two-stage bending allows the use of less-than-perfectly straight-grained wood strips in bending small radii because the strips are bent in stages.

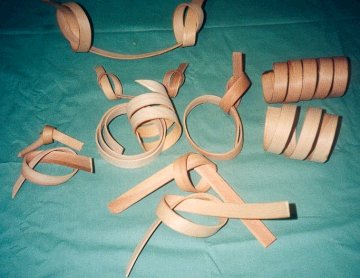

Examples of different radii and shapes that can be produced using the improved method. Original length of the strips ranged from 4 to 40 inches.

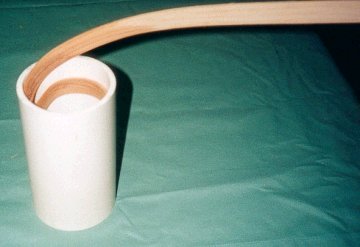

3 inch-diameter PVC pipe with partially-inserted 1inch wide heated, water-soaked strip. A strip this long will generally have to be reinserted into the boiling water tank 2 or 3 times before the strip is completely loaded into the form.

What’s for dinner? Western juniper can make some interesting table-setting items for that rustic look.